Our Services

We have the expertise and state-of-the art to offer the following:

Rewinding work for AC / DC motorsRepairing and Maintenance work for AC / DC Motors / HT Motors

Rewinding work for AC Generators

Repairing and Maintenance work for AC Generators

Rewinding work for EMS Coils

Repairing and Maintenance work for EMS Coils

Manufacturer and Suppliers Of EMS Coils

Our team members have a vast range of rewinding and associated skills for the repair of Electric Motors including Steel, Mining, Power Generation & Test and Inspections.

Mining, Power Generation & Test and Inspections With years of experience in our team

Generator SpecialistsLead Winders

Winding Specialists

Team Winders

Trainee Winders

Diesel Mechanics

Kishore Windwell is able to supply supervision and winding teams for all aspects of your gearless motor drive or large mill installation or provide rewinding, repairing & maintenance for all types of AC, DC motors, AC generators anywhere across India or overseas. Our teams have installed and rewound many mills across the country bringing a proven level of technical experience to your project.

Kishore Windwell can respond quickly to your request for urgent repairs bring it back in service with a cost effective and quality solution. We also offer complete testing and inspection of your large mill equipment. We at Kishore Windwell are fully experienced to work with any type of drive, as we are winding and rewinding specialists we can offer our experienced staff in all areas of machine rewinding irrespective of type of drive. Our Philosophy “Re-Invest” in Industry Specific Tooling & Equipments:

To support our quality services, we have strong tooling and testing

facility:

TOOLING & MACHINES

-

2 x 20′ Site Container Workshops Fully Equipped

-

Twin EFD Induction Welding Machines (with dedicated

refrigerated cooling unit)

-

Dry Ice Cleaning Machine

-

“On Site” Baking Oven

TOOLING & MACHINES

- 2 x 20′ Site Container Workshops Fully Equipped

- Twin EFD Induction Welding Machines (with dedicated refrigerated cooling unit)

- Dry Ice Cleaning Machine

- “On Site” Baking Oven

TESTING EQUIPMENT

- 28KV ‘VLF’ Hipot

- 10KV Digital Megger

- 100AMP Digital Micro OHM Meter (DLRO)

- 12KV Baker – Surge Comparison Tester

- 10amp Ductor Tester

- Corona Camera

- Boroscope

- Digital Hardness Tester

- Wedge Inspection Unit

We also manufacture and supply the following products:

- Electromagnetic Stirrer COILS

- Control Panel For Electromagnetic Stirrer

- Cooling Water System For EMS

- EMS For Billet

- Lifting Electromagnet

PREFERRED CONTRACTORS

Kishore Windwell takes pride on building several strong, long standing alliances and preferred contractors. In conjunction with our alliances and preferred contractors, we can also provide electrical engineering solutions.

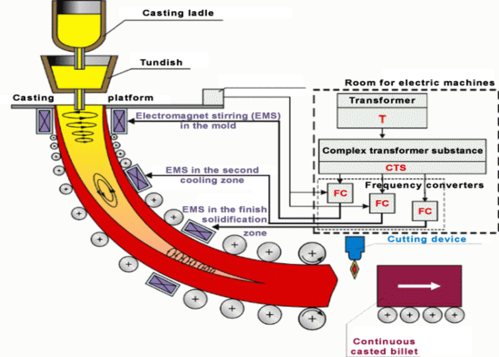

About EMS (Electro Magnetic Stirring System)

M-EMS AND S-EMS FOR BILLET AND BLOOM CASTERS

Electromagnetic stirring (EMS) improves quality and productivity in continuous casting. The rotating field induces magneto dynamic forces in the liquid steel producing rotational flow, thereby providing better heat transfer and gas release, improved equiaxed zone, and minimizing carbon segregation, inclusions, porosity, surface and internal cracks.

WHY KISHORE WINDWELL

We repair, recondition and total renovation of EMS of any brand

EMS coil windings are subject to wear during operation. Wear causes a progressive degradation of the insulation properties of the coils, causing loss of ground insulation. In addition, accidental events (like insufficient water cooling, steel overflows, etc.) can damage the materials, causing significant reduction of the EMS performance.

Kishore Windwell offers a qualified and efficient Service of reconditioning or complete renovation of EMSs of any brand:

Proprietary re-insulation treatment

Reconstruction of windings

Complete EMS renovation

Final electric and hydraulic testing

Complete technical reporting

The Kishore Windwell renovation technologies give the reconditioned stirrers insulation and lifetime properties significantly higher than the original new equipment.

Our stirrer strongly reduces white porosity bonds. Due to good and lasting insulation the stirrer is free from breakdown and need less maintenance.

The brief scope of work for EMS COIL RECONDITIONING &

REWINDING is as under:-

1. Manufacturing of new coils.

2. Replacement of steel wedges.

3. Replacement of inters layer-insulating spacers.

4. Impregnation of coils.

5. Replacement of all terminal leads, brass studs,

insulating muffs etc.

6. Supply of terminal plate in S.S & it insulating bush.

Business Enquiry

Call us at +91 98224 13815

QUICK LINKS

OFFICE:

152/B, Shankarmath, Pune – Solapur Road,

Pune – 411013

WORKS

Survey No: 97/1,Plot No; 123,

Sub Plot No; 22, Lane No; 10,

Ramtekdi Industrial Estate,

Hadapsar, Pune - 411013

Landmark: OPPOSITE The Jaw's Company

kishorwindwell@hotmail.com / kishorewindwelloffice@gmail.com

Phone No.: +91 98224 13815

Contact Person: Mr. Kishore Shinde